On October 30, 2025, WBTL's Electro-Mechanical Braking (EMB) system was officially selected as the designated solution for a major Chinese automaker's all-electric mid-size to large luxury sedan series. The vehicle lineup will include both two-wheel and four-wheel drive versions, all equipped with WBTL's EMB system as standard. This project places extremely high demands on braking performance and quality reliability, underscoring the customer's strong confidence in WBTL's EMB technological capabilities.

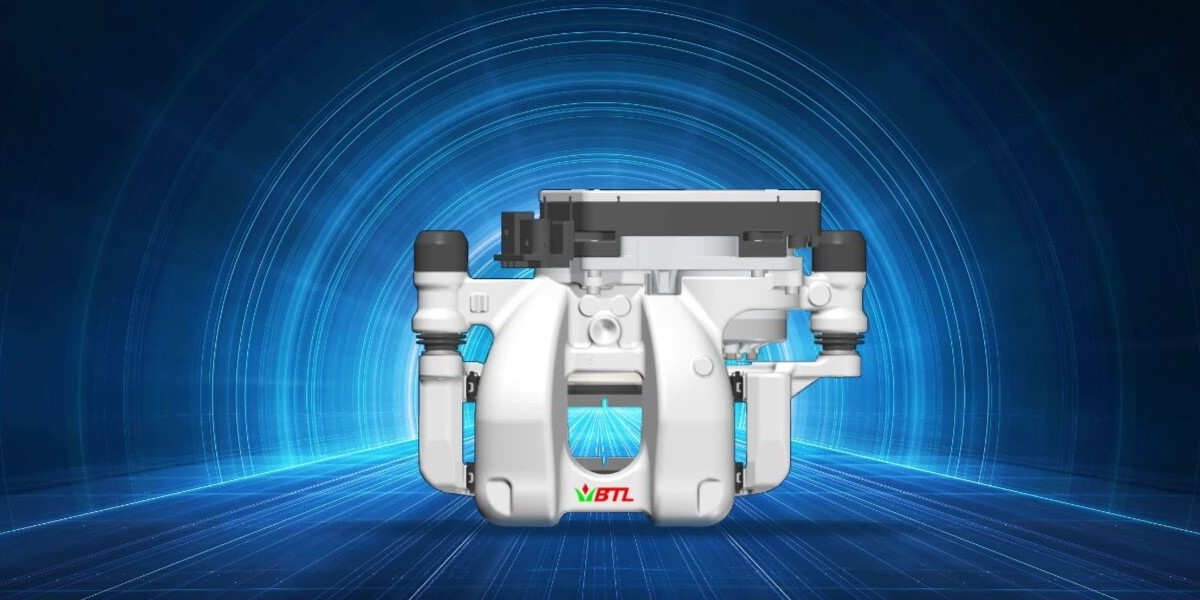

WBTL's EMB system utilizes a proprietary high-precision clamping force algorithm, which eliminates the need for pressure sensors, optimizes the system architecture, enhances robustness, and facilitates easier vehicle integration. The industry-first Reverse-Guide-Pin design reduces caliper sliding resistance and, combined with advanced software algorithms, enables “zero drag” braking performance.

Key system features include:

- Individual control of all four calipers, supporting L3 and higher autonomous driving;

- Response time: TTL ≤ 100ms;

- Compliance with ASIL-D functional safety standards;

- Multiple advanced functions, including VMC, tire-blowout stability control, and ideal braking force distribution;

- Wheel-end WCU single-point failure safety, ensuring deceleration ≥ 0.65g;

- Redundant central controller (CCU) with dual backup—single-point failure does not affect braking performance.

The project selection followed months of intense competition against several international component suppliers, with WBTL ultimately securing the contract. As a critical braking product, quality and safety are of utmost importance. WBTL has a proven track record in the mass production and quality control of Electro-Mechanical Braking products: cumulative production of Electronic Parking Brake (EPB) systems has exceeded 20 million units, brake calipers has exceeded 26 million units, and the One-Box Wire-Controlled Braking System (WCBS) has reached a stable annual supply capacity of 2 million units.

Leveraging highly synergistic core manufacturing processes, a deeply integrated supply chain, and consistent production and quality standards, WBTL has established a solid foundation for the rapid and reliable industrialization of its EMB system.

This marks WBTL's second EMB mass-production development project. Since commencing volume production of its first brake assembly in 2005, WBTL has rapidly gained market recognition through advanced technology and cost competitiveness. In 2012, the company became the first in China and the second globally to achieve mass production of EPB, setting a milestone for domestic electro-mechanical braking systems. In 2021, WBTL again led the industry as the first Chinese brand to launch and mass-produce a One-Box wire-controlled braking system, further strengthening its leadership in braking technology.

These achievements are no coincidence—they are the result of WBTL's long-term expertise, integrated capabilities, and continuous innovation in chassis systems. With ongoing R&D focus in the intelligent chassis domain, WBTL has strategically positioned itself across four key business areas: braking, steering, suspension, and assisted autonomous driving. Through multi-system collaboration and continuous technological integration, the company is committed to driving breakthroughs in core products.

The year 2026 is expected to mark the beginning of large-scale EMB adoption in the Chinese market, bringing transformative changes to chassis technology. Seizing this historic opportunity, multiple domestic automakers are already preparing for the initial mass production of EMB systems. WBTL remains dedicated to innovation and safety. The company aims to collaborate closely with automakers to promote the safe and intelligent implementation of cutting-edge technologies like EMB. Together, we strive to set new global benchmarks and open a new chapter for the future of smart mobility.

Copyright 2009 芜湖伯特利汽车安全系统股份有限公司 皖ICP备15022048号 Technical support:海拔网络